- Peelamedu, Coimbatore-641004

- Sun to Friday: 10.00 am - 7.00 pm

Manufacturing Process

- Home

- Manufacturing Process

Forging & Investment Casting

Crafting exceptionally strong and intricately shaped components with superior material integrity.

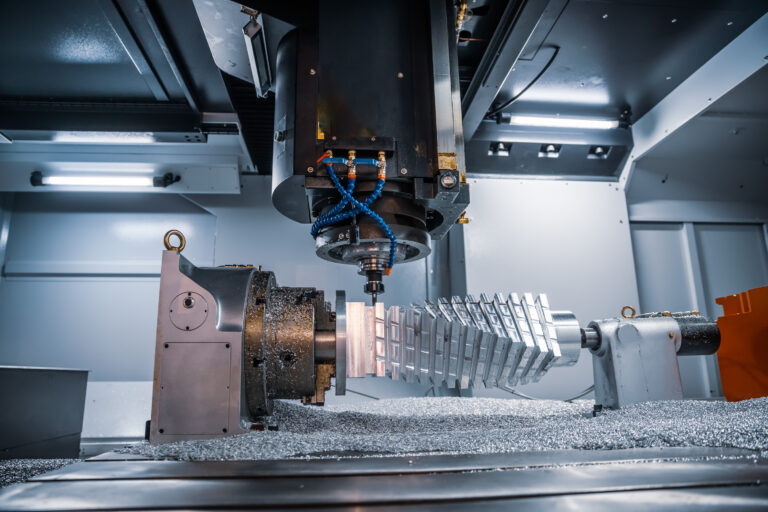

CNC Milling

Precisely shaping complex, multi-dimensional parts with advanced computer-controlled accuracy.

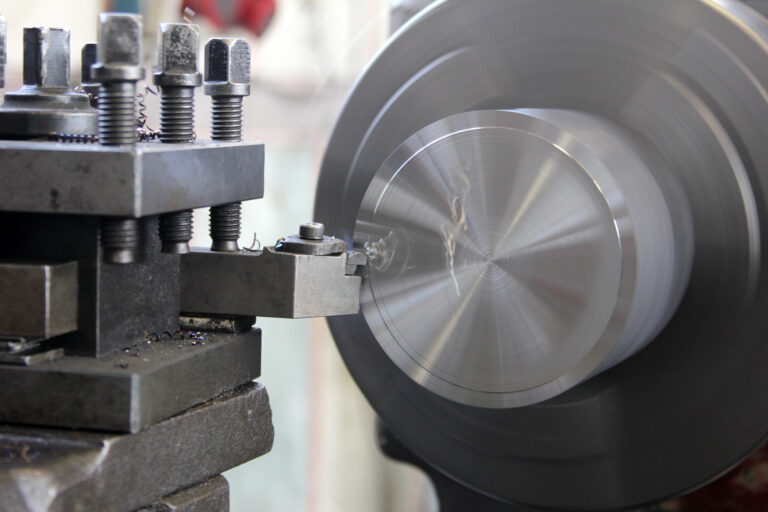

CNC Turning

Producing high-precision cylindrical components with speed and unwavering dimensional consistency.

Laser Cutting

Precision cutting of materials using a high-powered laser beam.

Waterjet Cutting

Cutting materials with a high-pressure stream of water, often with abrasives.

Sheet Metal Forming & Punching

Expertly forming and punching various sheet metals into precise custom shapes and features.Creating holes or shapes in sheet metal by pressing a punch through it.

EDM Cutting

Machining through electrically conductive materials using electrical discharges.

Metal Surface Treatment

Enhancing component durability, performance, and finish through specialized surface modification processes.

Fasteners

Components used to mechanically join two or more objects together.

Welding & Assembly

Joining materials, typically metals, using heat and/or pressure, followed by putting components together to form a complete product.

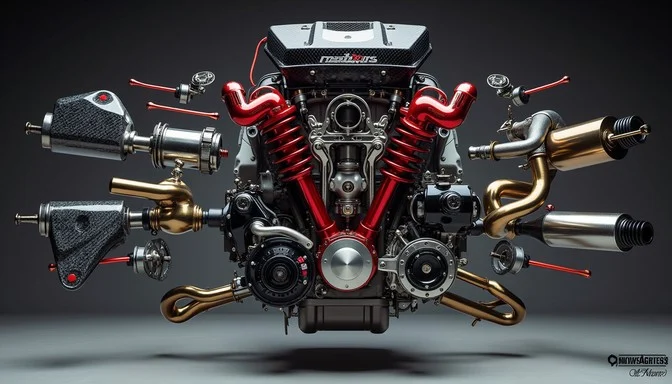

Forging & Investment Casting

We harness the power of both forging and investment casting to produce components with exceptional strength, intricate geometries, and superior surface finishes. Forging delivers parts with enhanced structural integrity and fatigue resistance, ideal for high-stress applications. Investment casting, on the other hand, allows us to create highly complex, near-net-shape components with unparalleled precision, reducing post-machining requirements and material waste. Our expertise in material selection and process optimization ensures the ideal method is chosen for your specific application, guaranteeing optimal mechanical properties and dimensional accuracy.

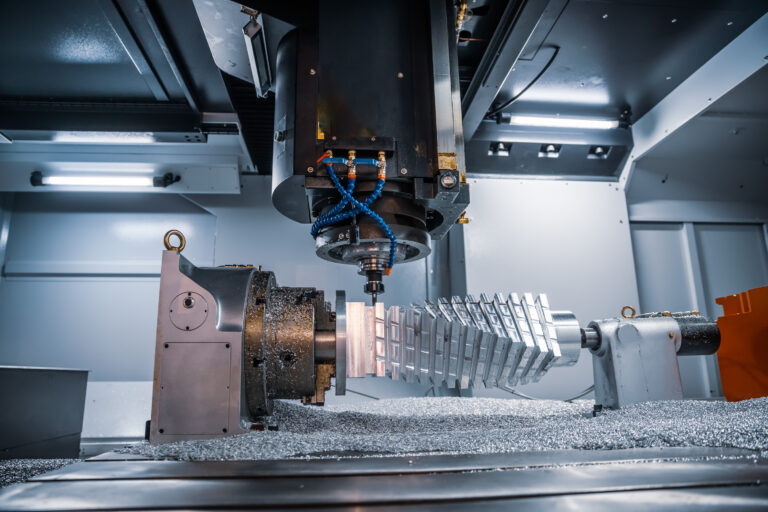

CNC Milling

Our advanced CNC (Computer Numerical Control) milling operations involve the precise removal of material using rotating multi-point cutting tools. This versatile process allows us to produce complex, three-dimensional shapes and intricate features with remarkable accuracy and repeatability across various materials. Equipped with multi-axis milling capabilities, we achieve tight tolerances and superior surface finishes, consistently delivering components that meet the most demanding specifications.

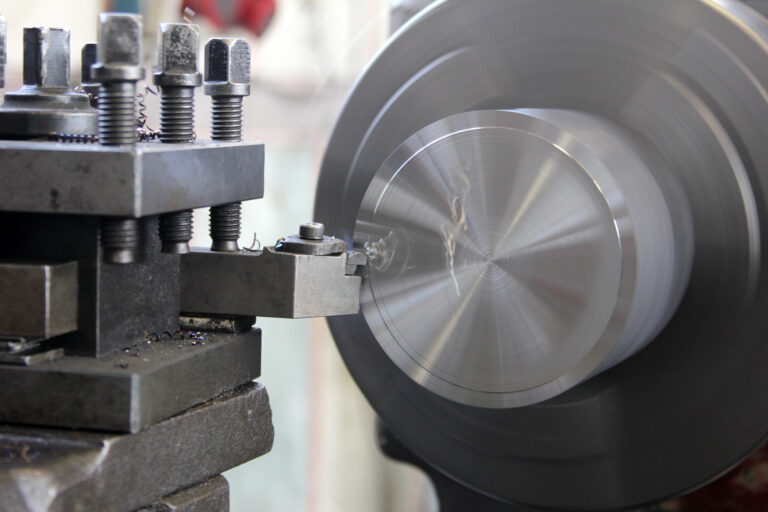

CNC Turning

Utilizing state-of-the-art CNC turning centers, we precisely shape cylindrical components by rotating the workpiece against a fixed cutting tool. This process is fundamental for producing a wide range of rotational parts, from simple shafts to complex contoured geometries. Our high-speed and precision turning capabilities ensure exceptional dimensional accuracy and surface quality for every cylindrical component, optimizing performance and fit.

Sheet Metal Forming

We offer comprehensive sheet metal capabilities, including precision bending and punching. Our advanced machinery allows us to create custom shapes and features from various sheet metal gauges, ensuring high accuracy and consistent quality for your enclosures, brackets, and panels. Combining advanced press brakes for precise bends and high-speed punching capabilities, we efficiently produce complex sheet metal parts with minimal waste and excellent repeatability.

Precision Cutting Technologies

Laser Cutting: Ideal for rapid, high-accuracy cutting of various metals, offering clean edges and minimal material distortion. Waterjet Cutting: Perfect for heat-sensitive materials and thick sections, providing burr-free cuts without heat-affected zones. EDM (Electrical Discharge Machining) Cutting: Utilized for intricate cuts on hardened metals and exotic alloys, achieving extreme precision and complex internal shapes that traditional machining cannot.

Metal Surface Treatment

Enhance the durability, corrosion resistance, aesthetics, and functional properties of your components with our comprehensive metal surface treatment services. This includes a range of processes such as heat treatment, plating, coating, and polishing, tailored to meet specific performance requirements. We ensure that your components not only meet dimensional specifications but also possess the optimal surface characteristics for their intended application, extending their lifespan and improving performance.Waterjet Cutting: Perfect for heat-sensitive materials and thick sections, providing burr-free cuts without heat-affected zones. EDM (Electrical Discharge Machining) Cutting: Utilized for intricate cuts on hardened metals and exotic alloys, achieving extreme precision and complex internal shapes that traditional machining cannot.

Welding & Assembly

We provide expert welding and assembly services to deliver complete sub-assemblies or ready-to-integrate products. Our skilled technicians utilize various welding techniques (e.g., TIG, MIG, Spot welding, as applicable) to ensure strong, precise joints, followed by meticulous assembly processes that guarantee the flawless integration of components. Our integrated welding and assembly capabilities offer a value-added service, reducing your complexity and ensuring your components are perfectly united for optimal functionality.EDM (Electrical Discharge Machining) Cutting: Utilized for intricate cuts on hardened metals and exotic alloys, achieving extreme precision and complex internal shapes that traditional machining cannot.

Laser Cutting

At Mahira Engineering, our Laser Cutting capabilities provide unparalleled precision and speed for cutting a wide array of materials. Using focused, high-power laser beams, we meticulously cut complex shapes and intricate designs with minimal heat distortion and excellent edge quality, making it an ideal solution for prototypes, custom parts, and high-volume production runs with efficiency and accuracy.

Waterjet Cutting

Mahira Engineering employs sophisticated Waterjet Cutting technology, offering a versatile and precise method for cutting virtually any material without heat-induced distortion. Our high-pressure abrasive waterjet streams enable us to create intricate shapes and clean edges on sensitive materials, composites, and thick metals, making it an excellent choice for applications requiring high precision and material integrity.

EDM Cutting

(Electrical Discharge Machining): Mahira Engineering provides specialized EDM Cutting services for precision machining of hard and difficult-to-machine conductive materials. This non-contact process uses electrical discharges to erode material, allowing us to produce extremely intricate shapes, fine details, and accurate cuts in hardened steels, exotic alloys, and complex geometries that are challenging for traditional machining methods.

Fasteners

Mahira Engineering understands the critical role of reliable connections, which is why we provide a wide range of high-quality Fasteners as part of our integrated solutions. We ensure the availability of appropriate fastening hardware, including screws, nuts, bolts, and custom solutions, to securely join components in your assemblies, guaranteeing structural integrity and ease of maintenance for your products.